+49 7161 8501-0

We print packaging.

Boundless

opportunities

Excellent accuracy and vivid colors.

Direct-to-container printing – on the cylindrical container of your choice.

Printing process of choice

Bring your products to life with high-end design and appearance. Let your imagination guide you – even in Pantone colors.

-

Bottlecan

Bottlecan -

Aluminum Wine Bottles

Aluminum Wine Bottles -

Aerosol Cans

Aerosol Cans -

Aerosol Cans

Aerosol Cans -

Plastic Tubes

Plastic Tubes -

Aluminum Tubes

Aluminum Tubes -

Aluminum Tubes

Aluminum Tubes -

Beverage Cans

Beverage Cans -

Beverage Cans

Beverage Cans -

Beverage Cans

Beverage Cans -

Beverage Cans

Beverage Cans -

Beverage Cans

Beverage Cans -

Beverage Cans

Beverage Cans -

Beverage Cans

Beverage Cans -

Rigid Containers

Rigid Containers -

Cartridges

Cartridges -

Bottles

Bottles -

Food Cans

Food Cans

Bottlecan

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

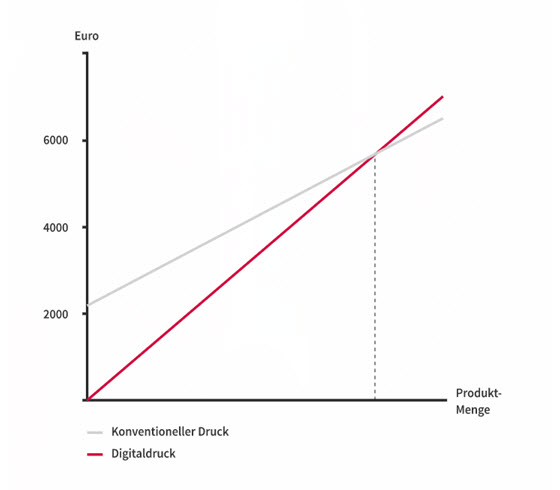

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

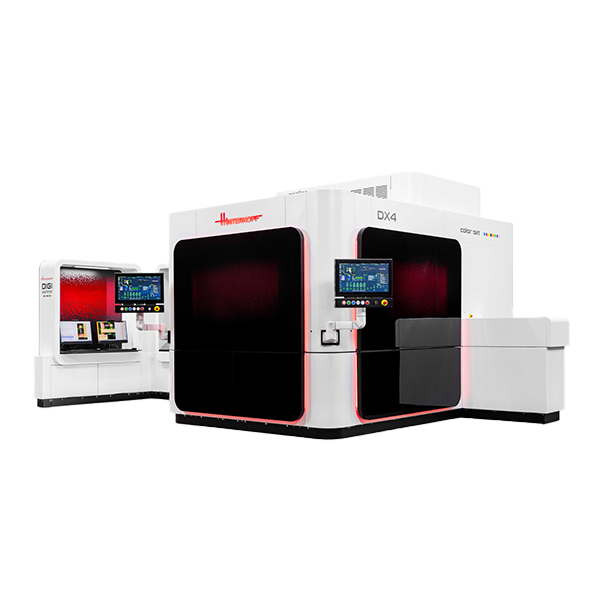

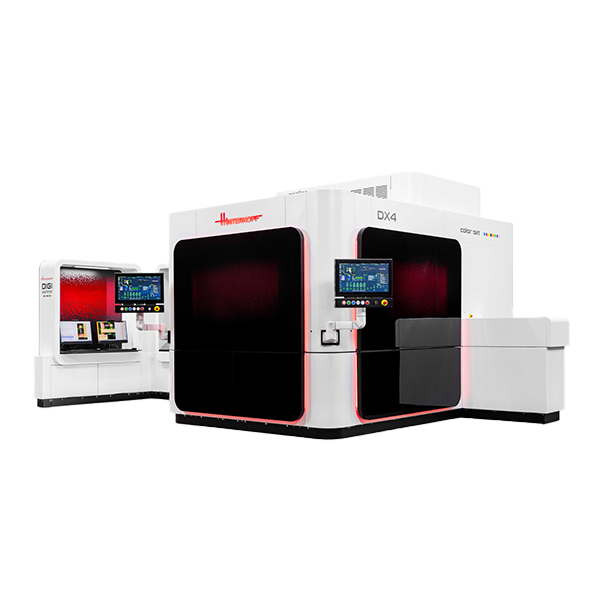

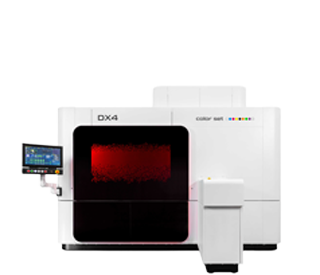

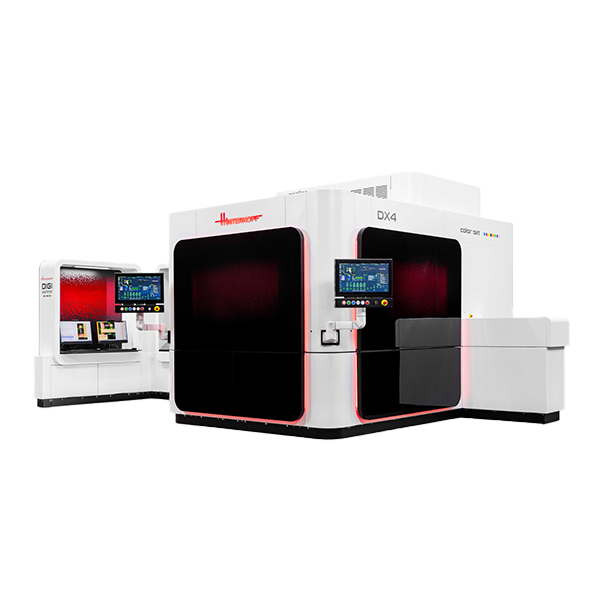

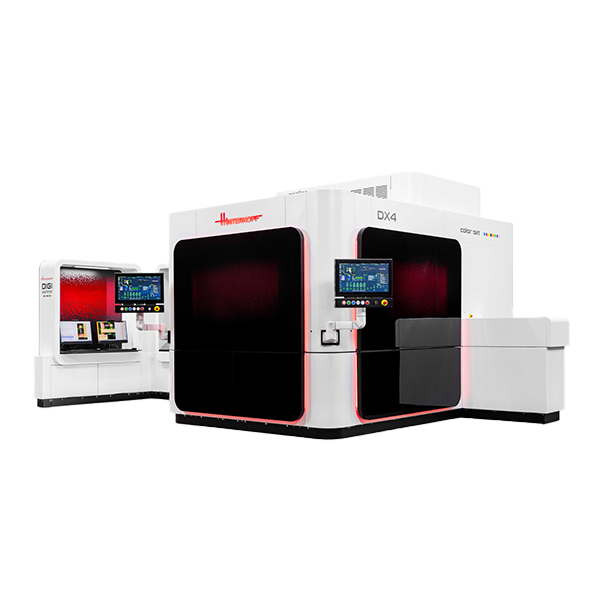

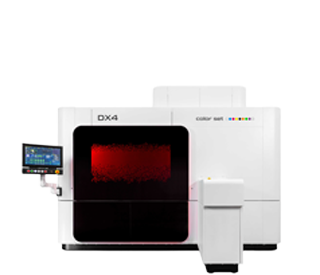

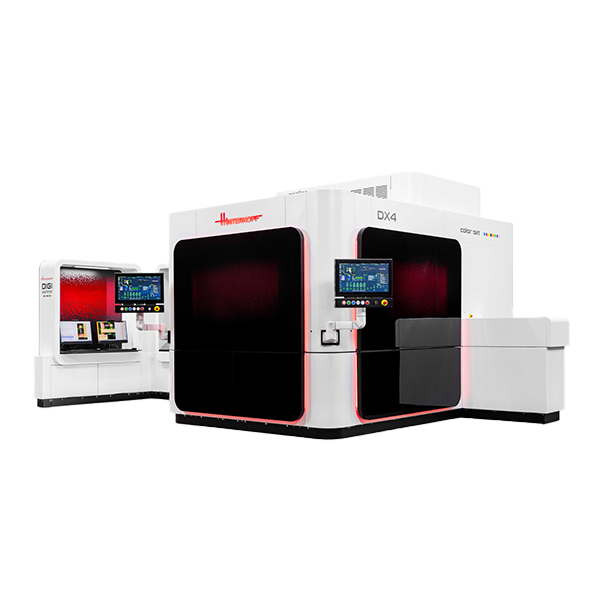

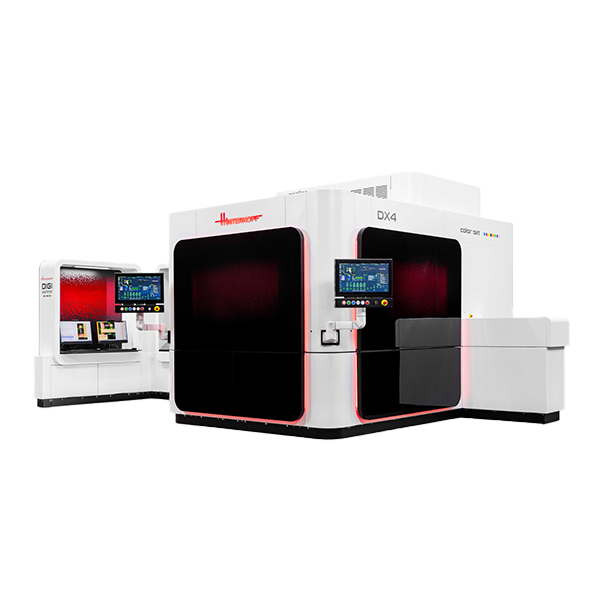

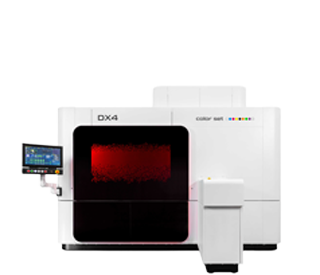

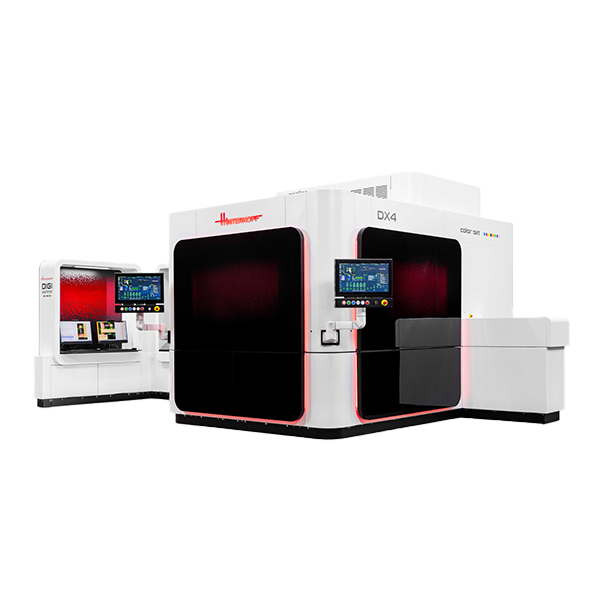

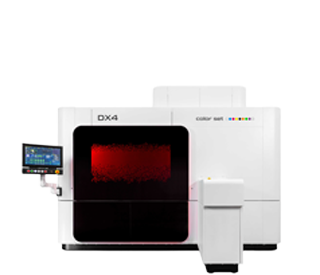

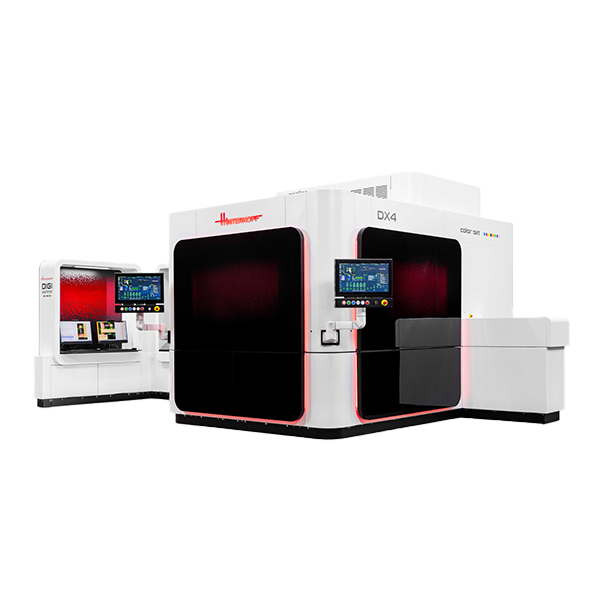

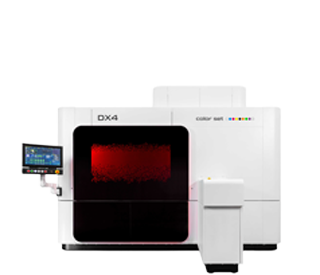

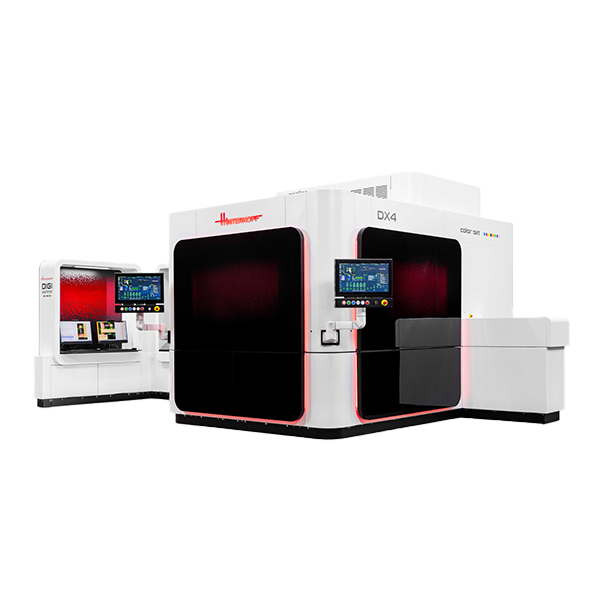

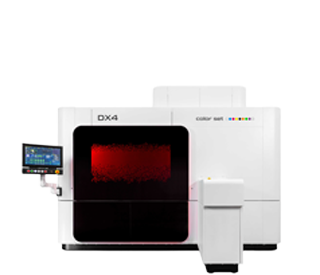

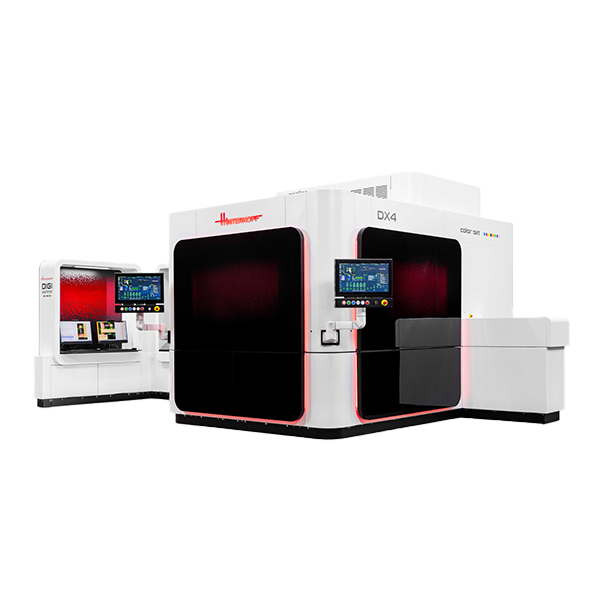

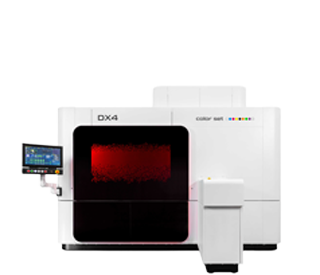

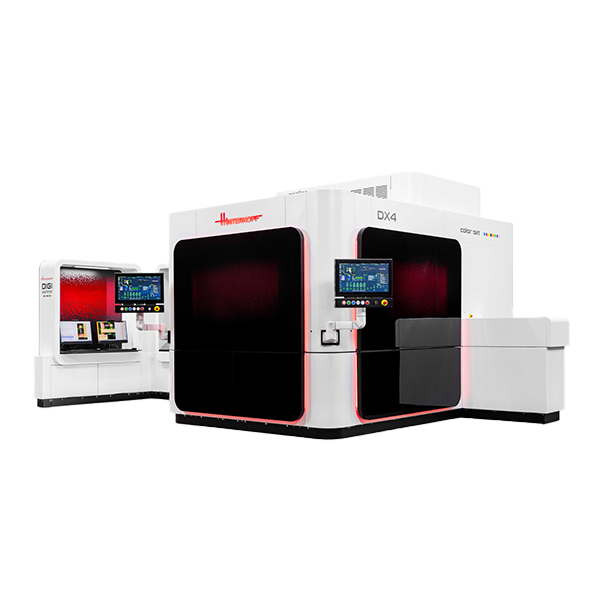

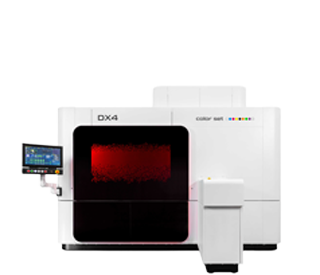

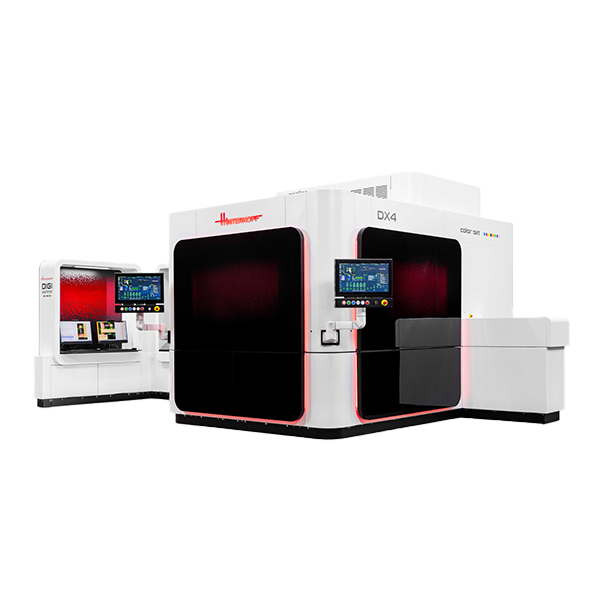

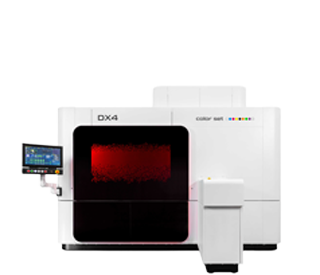

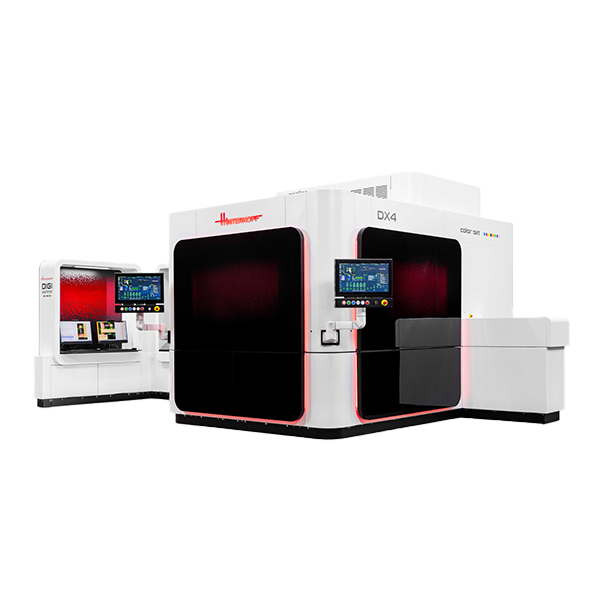

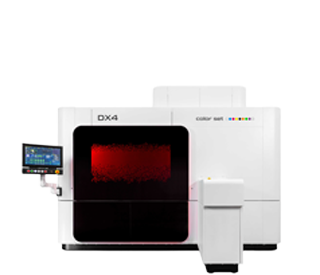

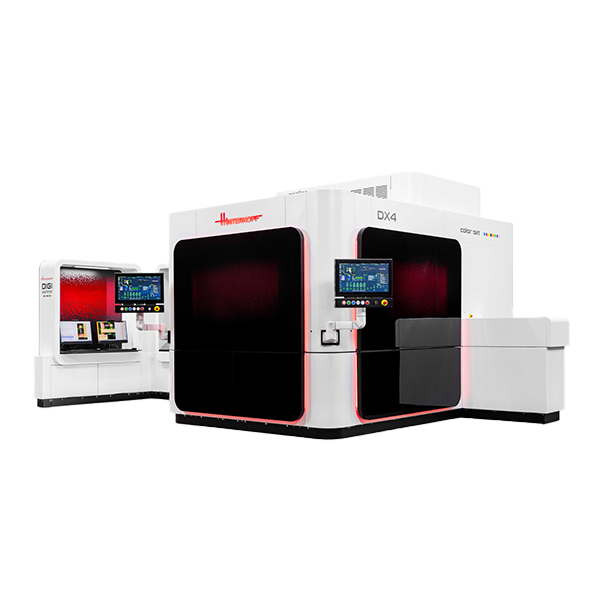

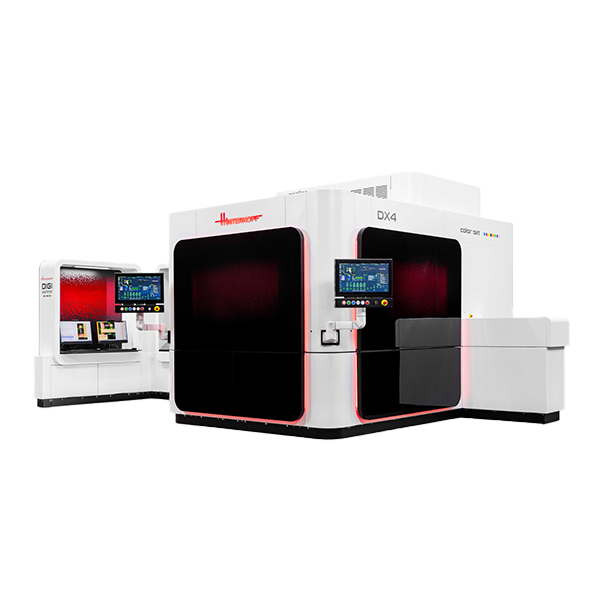

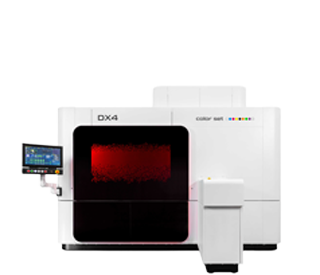

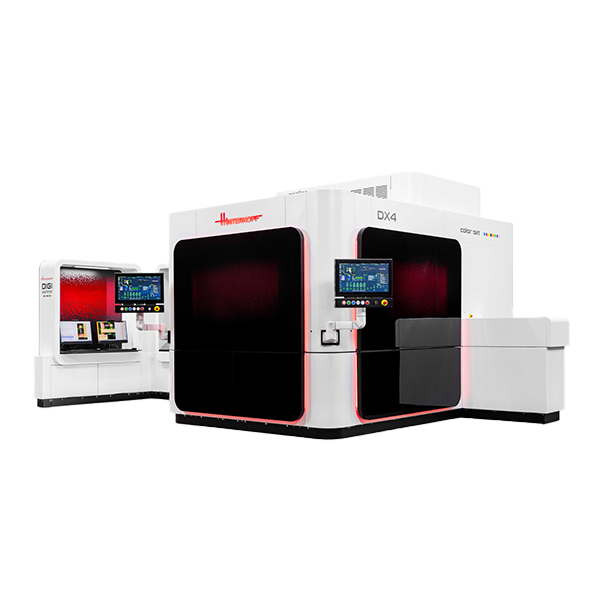

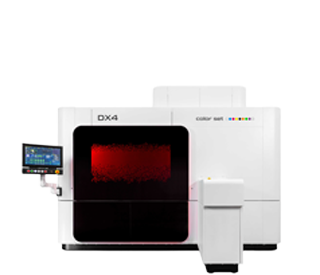

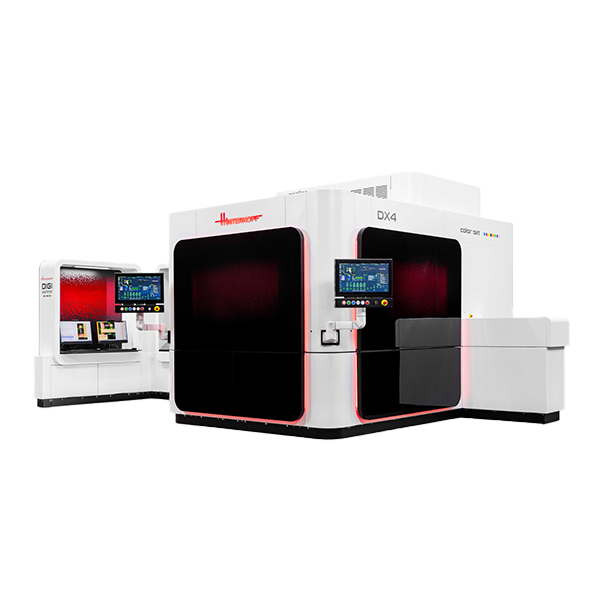

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Aluminium Wine Bottles

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Aerosol Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Aerosol Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Plastic Tubes

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Aluminum Tubes

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Aluminum Tubes

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Beverage Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Rigid Containers

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Cartridges

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Bottles

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

Umweltbewusst: Vom Design direkt zum Printprodukt

- Sparsamer Umgang mit Ressourcen

- Keine Druckplatten, Klischees oder Farbwalzen

- Print on Demand

- Keine Makulatur

- Digitaler Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

Food Cans

The ideal solution for your printing needs

- Outstanding print quality (up to 1600 dpi)

- Razor sharp text

- Photo-realistic images

- Optimum color saturation and coverage

- Matte and gloss effect

- Tactile surfaces

- No-overlap printing

- Pantone color space

- 360° printing, no lap-line

- Optimum color transition and shades

- Translucent colors

- Copyright-/IP-Protection

- Printing in neck/shoulder area

Digital printing is energy and resource efficiencient

- Zero change-over and set-up cost

- Economic production of minimum lot sizes

- Zero basic set-up and low variable cost

- Zero lost production time for production ramp-up

- Simple, linear cost structure per copy

- Predictable linear costing and estimating

- Increased productive time capacity

Environmentally responsible: From design idea to printed product

- Optimum resource efficiency

- No printing plates, films, ink rollers

- Print on Demand

- Zero print waste

- Digital Workflow

-

DX 4

-

D240.2

-

D360.4

-

D480.4

DX 4

- white, CMYK

- orange, green, violet

- Varnish/Spot

- 360° Printing / 2 point font size

- up to 1500 dpi

- up to 180 Container per minute

- 36

- 9

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.100 x 2.770 x 2.900mm

- ~16 Tons

- Diameters 9-165mm

- 60, 120, 180, 240mm

D240.2

- white, CMYK

- Special colors/Varnish

- Spot

- 360° Printing / 2 point font size

- up to 900 dpi

- 240 Container per minute

- 32

- 16

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.500 x 2.400 x 2.900mm

- 15 Tons

- Diameters 25-74mm

- 60, 120, 180, 240mm

D360.4

- 2x white, CMYK

- orange, green, violet,

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 40

- 20

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 4.800 x 2.930 x 2.900mm

- 19,5 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm

D480.4

- 2x white, CMYK

- orange, green, violet, anilox

- 2x Varnish/Spot

- 360° Printing / 2 point font size

- up to 1800 dpi

- 240 Container per minute

- 48

- 24

- cylindrical

- PE, PP, PET; AL, Glas, Steel

- Direct printing on containers

- 5.000 x 3.100 x 2.900mm

- 22 Tons

- Diameters 30-74mm

- 60, 120, 180, 240mm